Weighbridge software

Weighbridge software is used for managing scales and weighing data, and can be used with a mobile device or desktop computer.

- HERE are the characteristics and features of weighbridge software.

- HERE you can find what makes a weighbridge software easy to use?

- HERE you see differences between old and new way of weighing.

- HERE is benefits about weighbridge software.

- HERE is information about the modern solution - Saas flexible cloud service.

- HERE you will find important factors for good service provider.

- HERE is information about mobile friendly software.

- Find HERE more about information of industrial scales to connect software.

Weighbridge software is used for managing scales and weighing data, and can be used with a mobile device or desktop computer. The scales are connected to the software, which enables the weighing data produced by the scales to be transferred and utilized for various purposes.

The weighbridge software measures and manages weight-based material flows received, sent and transferred internally by the company. With the help of weighing software, you and all the stakeholders can form an overall picture of the various material flows easily in one place.

Weighing software is used in many industries including:

- Circular economy

- Energy industry

- Mining industry

- Port industry

- Logistics

- etc.

Typical materials to be weighed are bulk material products, fuels, waste, raw material handling, minerals, powders etc.

Typical users of the scale software are vehicle drivers, weighing operators, work management, production employees, customer service, and people working in warehouses and in shipping and receiving tasks.

Some synonyms that are commonly used for a weighbridge software are:

- Truck scale software

- Weighing software

- Scale software

- Platform scale software

Popular weighbridge software products in the market include: Tamtron Precision weighbridge software, mScales, Flintab Victoria, Scanvaegt System, ScanX.net, Mettler Toledo, Tamtron Scalex, Tamtron One Scalex etc.

.png?width=650&height=504&name=MicrosoftTeams-image%20(139).png)

The weighing software can be installed on a computer or it can be used as a more flexible SaaS cloud service, which is the modern solution. This way, the software can be used on a website browser or a mobile device anywhere, and it’s not tied to a specific location.

A traditional weighing system is only intended for internal use of the company. Typically in these legacy systems, data is sent one-way eg. as an email, whereas a weighbridge system enables shared data management with all users and stakeholders.

Each scale is connected to the service using a data transmission unit. The weighings are registered in the software’s database. The weighbridge software creates warehouse transactions from weighing events. Warehouse transactions can be transferred to different business systems, such as ERP, via API. Weighings can be connected to clients, contracts and orders and, if necessary, to construction sites, projects and customer’s locations.

There is a lot of legislation related to the weighing industry. The weighing service also helps you to use scales as required by laws and regulations.

When using a weighbridge software, you usually don’t need to use the scale’s own user interface when weighing, but instead use the software’s user interface. Before weighing, you can choose the product, storage location etc. When the weighing is started, you reset the scale and place the weighing load on the scale, and press the weighing button.

A weighbridge software brings all the information relevant for weighing in one place. A weighbridge software typically includes

- Product registers

- Customer registers

- Vehicle registers

- Weighing logs

- Weighing receipts

- Waybills

- Etc.

A weighbridge software is typically used to send or receive materials. For example, the company can sell and send raw materials, products, fuel, waste etc. Companies can also transfer materials internally from one of their own warehouses to another.

When weighing is done by using a weighbridge software, an event log is generated. The inventory balance is updated and material related to invoicing is created automatically. The weighbridge software is also used for reporting, and it makes long term reporting effortless.

In addition to the traditional features of the weighing service, it is typically possible to expand the services with, for example, the following features using additional modules:

- Features related to the maintenance of the scales, such as remote maintenance and condition monitoring.

- Device management of the scales.

- Monitoring compliance with the law.

- Automatic identification of the load being weighed.

- Access control, for example control of gates.

- Waste transfer documents.

- Automatic photography of the loads being weighed.

- Attaching documents and photos to weighings and loads.

- Sampling and analyses related to the loads.

- Connection to a local automation system, for example an automated warehouse.

/New_07_2023/Add-On%20modules_EN.jpg?width=686&height=438&name=Add-On%20modules_EN.jpg)

The more scales you have, the more important it is to have a uniform solution and process, and centralized data for weighing.

As mentioned above, a modern weighbridge system is a flexible SaaS solution that can be used from anywhere by anyone who is authorized to use it. Therefore, it’s not an advisable option to commit to a solution that is not a SaaS product.

Modern software enables the automation of workflows. You’ll also benefit from having a self-service option in the weighing software. A competent service provider of a weighbridge software can help develop and unify the processes of different locations and different scales.

Other essential characteristics and features in a weighbridge software are:

- Easy to use even when trying it for the first time

- Available in multiple languages

- Can be connected to any scale regardless of the brand of the scale

- A possibility to transfer data to business systems

- Open APIs: a standard way to transfer data

- Easy to update

- Also external stakeholders can use the software – not limited to internal use

- Data security (the right place to store data is not a PC)

- Maintenance free

- Versatile and flexible to use for reporting weighing data

- Easy to use on different devices, including occasional users

- Easy to integrate with other software and systems

/New_07_2023/mScales_weighing_service.png?width=700&height=404&name=mScales_weighing_service.png)

When looking for a service provider for a weighbridge software, check that their product includes above mentioned features, but also consider these other important factors:

- Constantly developing. A reliable weighbridge software service provider constantly develops their product further, and is perhaps even a pioneer in the industry. It is a safe choice to go with a service provider that is at the forefront of the industry.

- Good online support. In today's world, transactions have moved online. Make sure, that the service provider offers easy to use online channels for support, eg. a customer portal and a knowledge base.

- Adaptability. The software can be adapted to your business’s needs. You can also define weighing processes according to your needs.

- Modularity. You can choose the service package and the additional services you need.

What makes a weighbridge software easy to use? Firstly, it needs to be mobile friendly making it possible to use it from anywhere and by anyone. It is also easier and faster to use the software, if all users and specifically external users don’t need a username, but can instead use the software with a specific code. Compare this eg. to picking up a package from a postal parcel machine using a code.

Before making the decision, always ask for a demo to see how the software works in practice. This is the fastest way to see if everything makes sense and seems logical.

Furthermore, to recognize an easy to use weighbridge software, the best way is to try it yourself. Is it easy to use without a user guide? Does the application itself guide you through its use? It’s particularly useful if external users can use the software by themselves from the first time without an introduction.

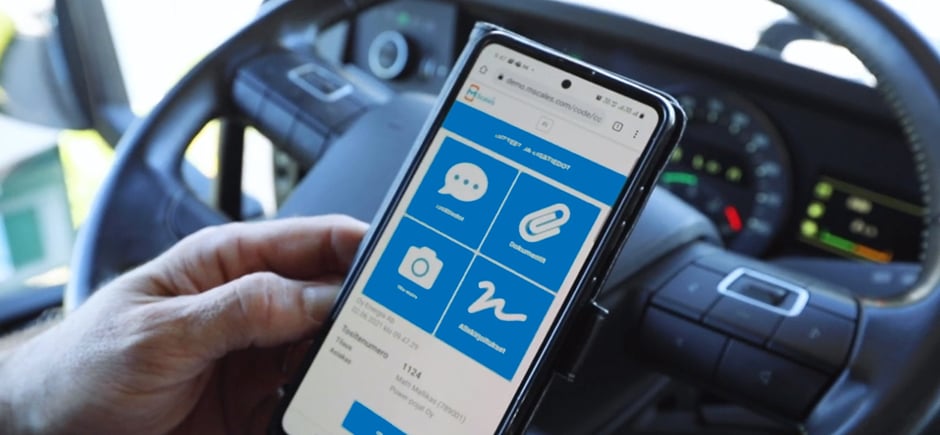

The majority of software usage today is done on mobile devices with screens of varying sizes. The modern weighbridge application scales well for different screen sizes. Users are also offered support where they are, which is in the application itself.

Nowadays everyone has their own user interface in their pocket in the form of smartphones. It goes where you go, and also the documents are always at your fingertips. Mobile use often means good work safety, because the driver does not have to get out of the vehicle.

Thanks to mobile use, the information on the weighbridge software is always correct and up-to-date. Updating the software is also remarkably efficient, and the latest updates are always available to the user.

Generally speaking, software is typically intended to make work more efficient, which is also the case with weighbridge software. It can be used to automate routines and reduce manual work.

Traditionally, scales have been connected to a lot of additional parts, such as a user terminal, printers, remote sensors and a PC computer. This way of using weighing systems and managing data is outdated and laborious. Traditional weighing system:

/New_07_2023/ERP_old_weighing.jpg?width=465&height=395&name=ERP_old_weighing.jpg)

Typically, there are several different people who need access to weighing data. The products have a supplier, a transport company and a customer, each of which has several people in different roles who process information. The weighing service enables the visibility and management of data for all parties according to their different roles.

This results in considerable cost savings due to the efficiency of the processes.

The benefits of a cloud-based service are the traceability of weighings anywhere and at any time, because all the information is in the same system. The service can be used with an internet browser or with a mobile application designed for its use.

Nowadays, the importance of traceability and compliance with the law is being emphasized, and weighing software makes operations more transparent and traceable. Information is made available to those who need it. Also the weighing information is always up-to-date: Each weighing updates inventory balances, reports and billing information in real time.

In addition, weighbridge software enables better customer service to the end customer.

The old way of weighing:

- Legacy systems: A scale specific Windows-based software and equipment with many maintenance and safety issues.

- Siloed and fragmented: Each location has its own information and methods of operating. Measurement results are not integrated into sales and purchase orders.

- Concentrated on the workforce: The systems are only intended for use by local field personnel.

- Cloud-based and mobile: All scales are connected to and maintained in the cloud service.

- Integrated platform: Scales and weighing data are shared with all the stakeholders. Material transactions are assigned directly to sales and purchase orders.

- Less need for manpower: The management of the scale and related data is automated.

/New_07_2023/mScales_before_after.png?width=730&height=309&name=mScales_before_after.png)

You can connect all kinds of scales to a weighbridge system from old to new ones. As mentioned above, you should consider choosing a weighbridge software to which you can connect scales from all the scale brands and not just a specific one.

There are many weighbridge software solutions in the market that only support one manufacturer’s scales, but for example mScales weighbridge software supports scales regardless of the brand. This way, you won’t need to change to a new weigbridge software when you get new scales from different brands.

The kind of industrial scales you can connect to the software are for example:

- Floor scales

- Truck scales

- Belt scales

- Silo scales

- Loader scales

A modern weighing software enables data to be transferred based on events and is always up-to-date, unlike the old system, where updates are made on a daily basis. The data of all different locations can be transferred efficiently and up-to-date to different business systems and wherever information is needed. The weighing service complements the features of the business systems and works as a seamless part of the overall architecture of the systems.

Therefore it is important that the weighbridge software can be connected to the ERP system used by your company. This is done by using a ready-made API interface, through which all scales can be connected.

The weighbridge software can also be integrated to online stores and transportation management systems.

The goal of the integrations is to make information flow in real-time, and keep invoicing, reporting and inventory balance always up-to-date in the ERP. In this way, traceability and controllability are significantly improved, and the operations are made transparent.