What We Do

Build your company website using drag-and-drop.

Vestibulum ac diam sit amet quam vehicula elementum sed sit amet dui. Vivamus suscipit tortor eget felis porttitor volutpat.

Vestibulum ac diam sit amet quam vehicula elementum sed sit amet dui. Vivamus suscipit tortor eget felis porttitor volutpat.

-

Lorem ipsum dolor sit amet

-

Lorem ipsum dolor sit amet

-

Lorem ipsum dolor sit amet

HubSpot CMS

The headline and subheader tells us what you're offering, and the form header closes the deal.

HubSpot Integrations

The headline and subheader tells us what you're offering, and the form header closes the deal.

SEO + PPC

The headline and subheader tells us what you're offering, and the form header closes the deal.

Site Speed Optimization

The headline and subheader tells us what you're offering, and the form header closes the deal.

Technical Consulting

The headline and subheader tells us what you're offering, and the form header closes the deal.

Team Training

The headline and subheader tells us what you're offering, and the form header closes the deal.

How to Improve Your Weighing Process

Find out 30 Effective ways from our blog

1. Connect All Scales to One System and Manage Material Flow Efficiently

Connect all scales to a single system, regardless of manufacturer, scale type, or age.

2. Use a Cloud-Based ERP to Manage Scales and Support Business Growth

Connect your scales to a modern, evolving cloud-based ERP system.

3. Start Self-Service Weighing to Streamline Operations

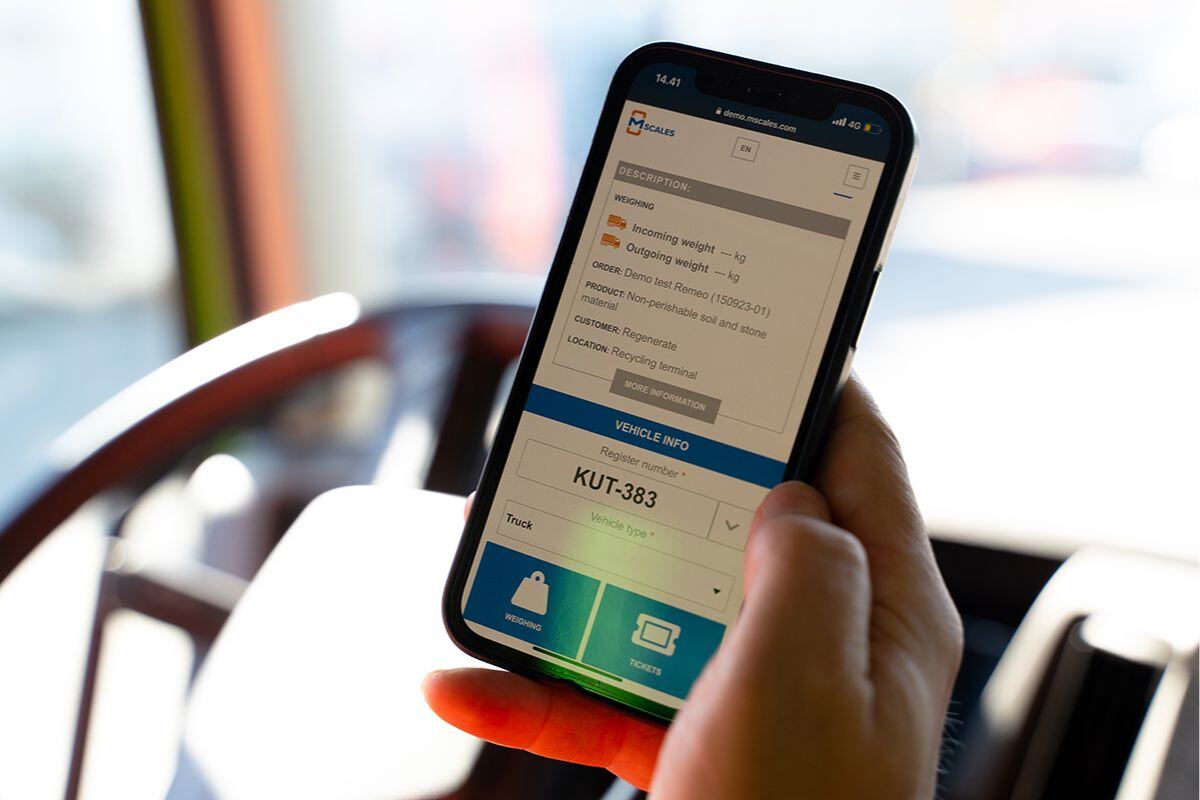

Self-service weighing enables streamlined operations and improves customer experience by providing 24/7 availability.

4. Store All Weighing Data in One Repository to Enhance Processes

This also enhances user and customer experience while significantly streamlining processes.

5. Share Real-Time Data with Partners and Stakeholders

Sharing real-time weighing data with partners and material flow stakeholders streamlines operations and improves customer satisfaction.

6. Take Control to Inventory and Say Goodbye to Excel Sheets

A modern weighing and material flow management service maintains up-to-date inventory automatically, and inventory events can be easily transferred to your ERP system.

7. Focus on Starting Supply Chains and Processes Effectively

Effectively starting processes is a key part of supply chain management.

8. Improve the Ad Hoc Reception Process for Better Customer Experience

Many customers face challenges with excessive ad hoc receptions.

9. Create an Order-Based Approach to Enhance Efficiency

Always link weighing events to business entities, such as orders, contracts, or tasks.

10. Standardize operational practices and data management across locations

The fragmentation of weighing systems and poorly defined processes have led to varied and localized practices.

11. Centralize Service Weighing to a Remote Service Center

This centralized approach increases resource

flexibility, and with modern digital tools, implementing it is straightforward and effective.

12. Enable Field Work and Streamline Processes

A modern weighing and material flow management service allows work to be performed from the field.

13. Provide transaction codes to users for simplified processes

A modern weighing system enables the use of reception and pickup codes in self-service.

14. Automate Transaction Code Management to Enhance User Experience

Traditionally, weighing systems have used identification tags or cards for material reception and shipment, with distribution and management being highly labor-intensive.

15. Integrate Systems Comprehensively for Enhanced Scalability

The traditional point-to-point integration approach, where two systems are directly connected, has been limiting and difficult to scale.

16. Minimize weighing equipment and modernize remaining scales

Investments in industrial scales are costly, but the scale itself often has a long lifespan, up to 20 years.

17. Enable Remote Maintenance and Condition Monitoring

Miro gives hosts the tools they need to make A modern digital weighing service enables remote monitoring, diagnostics, and maintenance of scales in a secure manner.

18. Choose a Solution That Meets Current and Future Regulations

Transitioning to cloud-based software solutions ensures compliance with regulatory requirements in real-time without costly updates.

19. Transfer Weighing Data to a Central Repository and Use Analytics

Today, data has become valuable capital, and companies have their own data warehouse and data lake solutions for managing information.

20. Choose Partners Who Are Industry Leaders and Continuously Evolving

When you select partners who are industry leaders and forerunners, and consistently evolving, you align your business with growth and development in the right direction.

21. Use System Upgrades as an Opportunity for Improvement

Modernizing and upgrading systems with a skilled partner provides an excellent opportunity to renew processes and practices.

22. Understand the Full Value Chain, From Your Customer to Theirs

Understanding the value chain and considering the entire customer journey, including your customers' customers, can add significant value to your business.

23. Boost Efficiency with Multi-Company Environment Features

Several companies would benefit from sharing the same weighing scale if it were easily achievable.

24. Share Pickup and Receiving Codes Through Your Logistics System

If you use an ERP, order supply chain system, or specialized logistics system, you can integrate transport management with material flow measurement into a single seamless process.

25. Use Logistics Scales to Monitor and Improve Efficiency

Many industrial scales are logistics scales, through which the products, raw materials, fuels and waste received and sent by the company pass.

26. Measure Each Product in the Load Separately

With a modern weighing service, you can unload or load in stages, measuring the amount of each product separately.

27. Identify and Manage Internal Material Flows in Production

Companies often focus on tracking material flows required by regulations, while internal material flows in production, such as bulk material handling, may receive less attention.

28. Improve Traceability with Enhanced Load Tracking

A modern weighing service enables automatic photographing, identification, and analysis of loads being weighed.

29. Enhance Receiving Inspections with Automation and Centralized Data

Perform receiving inspections based on automated monitoring and on-site observations, recording inspection data directly for each material transaction.

30. Use Pre-Notifications and Transfer Document Data Efficiency

Current regulations require pre-notification and specific transfer documentation, such as for waste transport at the start of a journey.