mScales weighing service / Blog / Digital Weighing Eliminates the Challenges of Tags

Digital Weighing Eliminates the Challenges of Tags

An RFID (Radio Frequency Identification) tag is an electronic device used for identification purposes. The use of tags is common in the logistics industry because they allow real-time tracking and management of product handling and the handling, positioning and transport of various transport packages, and provide access and weighing authorisations to the site. They are used in areas such as warehouse management, inventory management, product tracking and tracing and package tracking. The use of RFID tags reduces the need for manual work and improves the accuracy and availability of data, making it easier for companies to manage logistics and costs.

In general, professional drivers use physical weighing tags to record the weight of a load before departing. The contractor ensures the driver has the appropriate authorisation to weigh, load, or unload the cargo. Weighing slips are typically printed documents that serve as proof the load has been weighed and its weight recorded. These slips are also used in customs and taxation processes.

A weighing tag is typically a plastic card, about the size of a debit card, given to the driver to weigh the vehicle. It usually includes details such as the vehicle, product, and customer information stored on it. When the vehicle arrives at the weighbridge, the load is weighed, and the result is recorded on the weighing tag. A weighing slip and/or consignment note may be printed. The driver can then present the transport documents to authorities if requested. The weight of the vehicle varies depending on the load and the vehicle’s capacity.

Professional drivers use weighing tags to ensure their vehicle remains within legal weight limits. Some roads and bridges have weight restrictions to prevent infrastructure damage. Overweight vehicles also pose safety risks. The weighing tag, often placed above the truck’s cab window, displays information such as total weight, axle weights, and load weight. This helps the driver monitor and stay within permitted limits.

Trucks, semi-trailers, and vehicle combinations (e.g. with air suspension) are often equipped with axle weight measurement systems. These systems estimate the weight of each axle. For example, the so-called SmartBoard can collect axle weight data via CAN bus connections. TEBS E by Wabco is one such system available on the market. mScales, on the other hand, allows companies to define net weight limits per order or set total maximum weight limits with tolerances.

What Information Is Stored on the RFID Tag in the Truck Scale?

A truck's RFID tag stores information needed to measure and manage vehicle weight. Typically, it includes:

-

Weight: The RFID tag can store the load weight as measured by the truck scale.

-

Identification details: It may include vehicle data such as the registration number or vehicle type.

-

Transport documents: Transport-related documents can be linked to or stored on the RFID tag.

-

Timestamp: The system often stores the exact date and time of the weighing. This timestamp can also be written to the RFID tag.

-

Additional data: Other relevant information such as load contents, transport route, or handling instructions may be included.

-

Scale identification: The truck scale typically has a serial number or other identifier to ensure traceability and calibration.

-

Time and location: The date, time, and location of the weighing are commonly recorded in the system.

-

Vehicle weight data: The weighing tag may include total weight, axle weights, or axle group weights, depending on the system in use.

-

Weighing system information: This includes data such as register IDs, weighing capacity, and accuracy class.

-

Operator identification: The person performing the weighing, such as scale house staff, may log their user ID in the system or tag.

This information is usually stored either in the internal memory of the weighing scale or in a connected computer or cloud service for later access. It plays a key role in load management and vehicle weight monitoring and helps drivers and logistics operators comply with legal weight limits and safety regulations.

The specific data stored on an RFID tag may vary depending on its intended use and can differ between vehicles and systems. In addition, the weighing tag helps drivers avoid fines that may result from operating overweight vehicles in restricted areas. It is therefore an important tool for truck drivers transporting heavy goods.

Professional Driver — Is Your Weighing Tag Missing?

The physical weighing tag used by drivers can be lost or misplaced for several reasons. It may fall from the cab window or be left behind during loading. The tag may also get damaged or worn out, leading to errors or usability issues.

If a weighing tag is lost or damaged, it should be replaced. The weighing tag is a critical tool, and its use is often required by law. Drivers are responsible for always having a functional weighing tag or using a digital weighing system that stores all weighing data automatically in the cloud.

What Happens If the Weighing Tag Is Lost?

If a weighing tag is lost, it can cause problems. Firstly, you may not know the actual weight of the vehicle, which can lead to it being either overweight or underweight. This can be particularly dangerous when transporting hazardous goods or other sensitive materials. In addition, if you exceed the weight limit, you could face heavy fines.

Another issue caused by a lost weighing tag is that it may become difficult to operate the vehicle as intended. Many loading docks and ports require the use of a weighing tag to verify the vehicle's weight before loading can begin. Without a tag, you cannot prove the vehicle’s weight, which may prevent you from receiving your cargo or continuing your journey.

If you are a professional driver and are concerned about a lost weighing tag, you should check your local regulations and requirements. Some regions or countries may allow exceptions in certain cases, while others may require the use of a weighing tag in all situations.

However, today the weighing of vehicles and loads can be easily digitalised. All industrial scales can be connected to a digital weighing service that automates the process and eliminates manual steps and physical equipment.

How Can You Replace a Physical Weighing Tag?

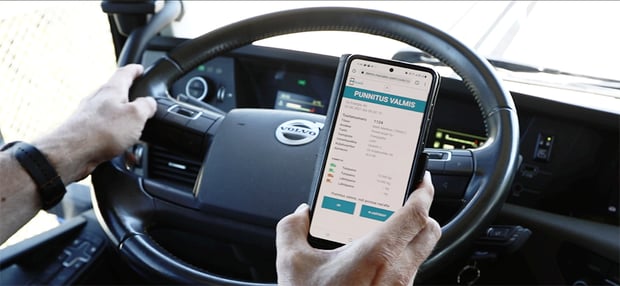

A physical weighing tag can be replaced by an electronic solution, which is often more accurate and easier to use. An electronic weighing device is usually a small, portable unit equipped with sensors, a display, and sometimes a printer. It can be connected to a vehicle’s weight measurement system and used to determine the vehicle’s weight in the same way as a traditional weighing tag.

Electronic weighing systems offer several advantages over physical tags. They are easier to handle because they are smaller and lighter, and they do not need to be physically attached to the vehicle. Their accuracy is generally better, as they use advanced sensors and technologies compared to physical tags. In addition, electronic solutions can be used with a wide range of vehicles and load types.

These systems are available from a wide range of manufacturers and suppliers, both for purchase and rental. The most important thing is to choose the right type of electronic weighing system for the specific vehicle and application. It is also essential to ensure that the system is properly calibrated and used correctly to obtain accurate weight data and avoid errors.

/New_07_2023/New_ENG_mScales_pick-up_code.png?width=480&height=333&name=New_ENG_mScales_pick-up_code.png)

Will Digital Weighing Also Replace the Weighing Tag?

Yes, the digital weighing method can replace the use of physical weighing tags and related manual devices. It uses electronic sensors to measure the weight of the vehicle and displays the result digitally on a screen. Digital weighing is therefore more reliable and accurate than traditional manual methods.

Fixed digital weighing systems are typically permanently installed in weighbridges and connected to a cloud service. The weight of the vehicle can be measured accurately and quickly when driving onto the scale.

The digital weighing method offers many advantages over traditional systems. Firstly, it is faster and easier to use, as there is no need for any physical attachment to the vehicle. Secondly, it is more accurate thanks to modern sensors and advanced technology. In addition, digital weighing systems automatically record the weighing data, which can then be used for load management and reporting.

When the scale is connected to a digital weighing service, there is no longer a need for physical RFID readers or tags. Manual work is significantly reduced, and human error is eliminated. The process becomes fully automated, and self-service weighing with weighing codes can be enabled. This approach leads to cost savings by eliminating peripheral equipment and making better use of working time.

Learn more: Replacing RFID Tags and Old Driver Terminals with Modern Technology

What Are the Benefits of Digital Load Weighing?

Digital load weighing offers many advantages over traditional weighing technologies. Some key benefits include:

-

Accuracy: Digital weighing provides higher precision than traditional methods, resulting in more reliable load measurements.

-

Speed: The weighing process is fast, saving time and improving overall operational efficiency.

-

Ease of use: Digital systems are easier to operate, reducing manual work and the risk of human error while enhancing the user experience.

-

Versatility: Digital weighing solutions can be used in a wide range of applications across different industries.

-

Automated measurement and recording: Weight data is measured and recorded automatically, making it easier to track, store, and analyse weighing results.

-

System integration: Digital weighing can be integrated with various logistics and warehouse systems, simplifying load management and traceability.

These benefits are especially important in the logistics sector, where speed, accuracy, and efficiency are critical. Digital load weighing helps transport companies optimise load handling, reduce errors, and lower costs—leading to significant overall savings.

In summary: Replacing the old physical tag with a digital solution using a weighing code improves safety, manageability, and cost-efficiency.

Want to discuss how mScales could benefit your business?

Book an appointment with an expert:

Contact:

Aleksi Sipilä

Sales Manager, mScales

+358 40 556 2666

aleksi.sipila@tamtron.com

Watch the video preview

Controlling material flow